What Are The Benefits Of Mining Cables

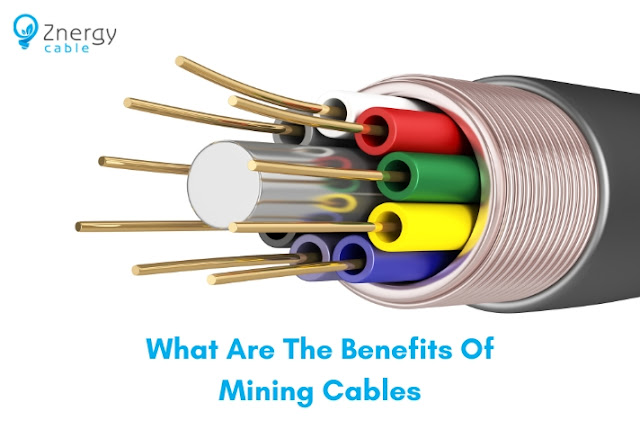

Mining cables are specialized electrical cables created specifically for use in mining situations where they must survive harsh temperatures and deliver dependable power transmission to mining machines and equipment.

These cables are designed to be strong, flexible, flame-resistant, and resistant to environmental conditions that are frequently present in mining activities.

It is advised to speak with reliable mining cable manufacturers or wholesalers who focus on mining cables for your particular cable needs, like type 241.1 cable. Based on the specific requirements and environmental factors of the mining operation, they can offer experienced advice on choosing the best cable.

10 Benefits of mining cable

Increased Safety and Decreased Downtime

The durability, flame resistance, and mechanical protection of mining cables reduce the possibility of electrical failures, cable damage, and fires, thereby increasing safety.

As a result, less unplanned downtime occurs, ensuring uninterrupted mining operations and higher output.

Industry standards

Mining cables must meet stringent industry standards and regulations in order to meet the performance and safety criteria needed for use in mining operations.

The reliability and operational safety of the cables are guaranteed by adherence to these criteria.

Strong design

Mining cables are made to withstand challenging environmental factors like abrasion, impact, and exposure to chemicals and oils that are frequently found at mining sites.

For superior mechanical protection against crushing and hard handling during installation and operation, they are frequently armored with steel wires or tapes.

Flexible as compared to other cables

Mining cables are made to be flexible and maneuverable, so they may pass down narrow passageways and around obstructions in underground mines or other confined locations.

Due to their flexibility, cables are less likely to be damaged during deployment, and installation is made simpler.

Weather resistance

Mining cables employed in surface mining operations are frequently made to survive exposure to ultraviolet (UV) radiation and severe weather.

While weatherproofing provides an uninterrupted power supply during inclement weather, UV-resistant clothing prevents deterioration caused by prolonged exposure to sunlight.

Compatibility with power equipment

Mining cables are available in a range of voltage ratings and sizes to meet the power needs of various pieces of mining machinery, including pumps, conveyors, drills, and ventilation systems.

Additionally, they work with a variety of connectors that are frequently employed in mining applications.

High Electrical Conductivity

High-quality copper conductors, which are used to make mining cables, provide good electrical conductivity.

As a result, there will be less power loss during transmission, enabling effective power distribution over the mining site.

Survive in harsh environmental conditions.

Mining cables are designed to withstand environmental conditions including dampness, dust, and severe temperatures that are frequently encountered in mining operations.

Even in challenging and severe conditions, these cables maintain their integrity and performance.

Flame and fire resistance

Mining cables are designed to be flame- and fire-resistant since safety in mining activities is of the utmost importance.

These cables feature specifically designed fire-retardant jackets that, in the case of a fire, limit the spread of flames and lower smoke emissions, improving the safety of people and property.

Longevity and durability

Mining cables are extremely durable, even under difficult operating conditions, due to their sturdy structure.

They outlast normal cables in terms of service life, which lessens the need for routine maintenance and cable replacements, which can be difficult and expensive in mining conditions.

Conclusion

Numerous advantages of mining cables are tailored specifically to the difficult and dangerous conditions of mining activities. These cables play a crucial role in ensuring the safe and effective transmission of power in mining environments, helping to increase productivity and decrease downtime.

This is due to their durable construction, resistance to environmental factors, flexibility, flame resistance, and compliance with industry standards.

For better performance and less electricity waste, you should contact trusted Australian cable manufacturer like Znergy Cable.

Znergy Cable is the leading electrical cable manufacturer in Australia. we design and manufacture mining cables, flexible power cables, solar cables, and more with compliance to safety measures.

Comments

Post a Comment