When to Use Heat Resistant Cables?

|

| Heat Resistant Cables |

Introduction:

Heat resistant cables and fire proof cables play a crucial role in various industries where exposure to high temperatures and fire hazards is a concern. Understanding when to use these specialized cables is essential for ensuring safety, reliability, and compliance with regulatory standards. In this comprehensive guide, we'll explore the differences between heat resistant cables and fire proof cables, their applications, and key considerations for selecting the right cable for your specific needs.

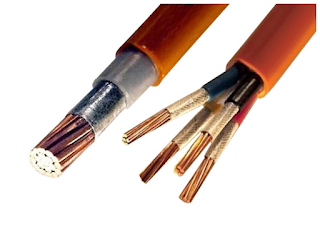

Understanding Heat Resistant Cables:

Heat resistant cables are designed to withstand elevated temperatures without compromising their performance or integrity. These cables are typically made from high-quality materials that offer excellent thermal resistance, such as silicone, fluoropolymers, and thermosetting plastics. Heat resistant cables are commonly used in applications where exposure to heat sources, such as ovens, furnaces, and industrial machinery, is a concern. They provide reliable power transmission and signal communication in high-temperature environments, ensuring safety and continuity of operations.Applications of Heat Resistant Cables:

Heat resistant cables find widespread use in various industries and applications where exposure to heat is a concern. Some common applications of heat resistant cables include:

- Industrial Machinery: Heat resistant cables are used to power and control electrical equipment in industrial settings, including machinery, motors, heaters, and sensors. They provide reliable performance in high-temperature environments, ensuring uninterrupted operation and safety.

- Aerospace and Defense: In the aerospace and defense industries, heat resistant cables are used in aircraft, missiles, satellites, and military vehicles to transmit power, data, and signals. These cables are designed to withstand extreme temperatures and harsh environmental conditions, ensuring reliability and durability in critical applications.

- Automotive: Heat resistant cables are essential components in automotive applications, including engine compartments, exhaust systems, and electrical wiring harnesses. They provide reliable power transmission and signal communication in high-temperature environments, ensuring the safety and performance of vehicles.

- Renewable Energy: Heat resistant cables are used in renewable energy systems, such as solar panels and wind turbines, to transmit power from the source to the grid or storage systems. These cables are designed to withstand exposure to sunlight, heat, and weathering, ensuring long-term reliability and efficiency.

Understanding Fireproof Cables:

Fire proof cables, also known as fire-resistant cables or fire-rated cables, are designed to maintain their functionality and integrity during a fire emergency. These cables are constructed with special materials and insulation that can withstand high temperatures and prevent the spread of fire. Fire proof cables are commonly used in buildings, tunnels, and other structures where fire safety is a priority. They provide critical communication and power transmission capabilities during a fire emergency, ensuring the safety of occupants and minimizing property damage.

Applications of Fireproof Cables:

Fire proof cables are essential components in fire safety systems and critical infrastructure where reliable communication and power transmission are essential during a fire emergency. Some common applications of fire proof cables include:

- Building Construction: Fireproof cables are used in the construction of commercial and residential buildings to provide fire-resistant wiring and communication infrastructure. These cables are installed in fire alarm systems, emergency lighting, sprinkler systems, and other critical components of fire safety systems.

- Transportation: Fireproof cables are used in transportation infrastructure, including tunnels, bridges, and underground railways, to provide reliable communication and power transmission capabilities during a fire emergency. These cables are designed to withstand exposure to high temperatures and flames, ensuring the safety of passengers and minimizing disruptions to transportation services.

- Industrial Facilities: Fireproof cables are used in industrial facilities, such as refineries, chemical plants, and power plants, to provide reliable power transmission and communication in high-risk environments. These cables are designed to withstand exposure to fire, heat, and chemicals, ensuring the safety of workers and preventing catastrophic accidents.

Key Considerations for Selecting the Right Cable:

When selecting between heat resistant cables and fire proof cables, several key considerations should be taken into account, including:

- Temperature Rating: Consider the maximum operating temperature of the cable and ensure that it can withstand the temperature conditions present in your application environment.

- Fire Resistance: Evaluate the fire resistance rating of the cable and ensure that it meets the regulatory requirements and standards for fire safety in your industry or application.

- Durability: Consider the durability and reliability of the cable in harsh environmental conditions, such as exposure to heat, moisture, chemicals, and mechanical stress.

- Compliance: Ensure that the cable complies with relevant regulatory standards and certifications for fire safety, electrical safety, and environmental protection.

Conclusion:

In conclusion, heat resistant cables and fire proof cables play critical roles in various industries and applications where exposure to high temperatures and fire hazards is a concern. Understanding the differences between these specialized cables and their applications is essential for ensuring safety, reliability, and compliance with regulatory standards. Whether you need heat resistant cables for industrial machinery or fire proof cables for building construction, selecting the right cable for your specific needs is crucial for maintaining safety and continuity of operations. By considering key factors such as temperature rating, fire resistance, durability, and compliance, you can make informed decisions and choose the right cable for your application requirements.

Comments

Post a Comment