Versatility and Precision of Stainless Steel Capillary Tubes

|

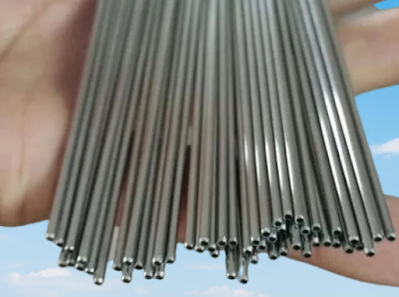

| Stainless Steel Capillary Tubes |

In the realm of precision engineering and fluid dynamics, one component stands out for its remarkable versatility and precision: the stainless steel capillary tube. Often overshadowed by larger and more conspicuous machinery, capillary tubes play a crucial role in a myriad of industries, from medical to aerospace, and beyond. In this comprehensive guide, we delve into the intricacies of stainless steel capillary tubes, exploring their applications, advantages, manufacturing process, and why they remain indispensable in various fields.

Understanding Capillary Tubes

Capillary tubes, as the name suggests, are slender tubes with very small internal diameters. Typically, these tubes have an outer diameter ranging from fractions of a millimeter to a few millimeters, while the inner diameter can be even smaller, sometimes measuring in micrometers. This minute scale makes capillary tubes adept at handling small amounts of fluids or gases with utmost precision.The Role of Stainless Steel

While capillary tubes can be manufactured from various materials such as plastics, glass, and metals, stainless steel emerges as a top choice for many applications. Stainless steel offers a unique combination of properties that make it ideal for capillary tubes:- Corrosion Resistance: Stainless steel exhibits exceptional resistance to corrosion, ensuring longevity and reliability, especially in demanding environments where exposure to moisture or harsh chemicals is prevalent.

- High Strength: Despite its slender dimensions, stainless steel capillary tubes boast remarkable strength and durability, capable of withstanding high pressures and mechanical stresses without deformation or failure.

- Temperature Stability: Stainless steel maintains its mechanical properties over a wide range of temperatures, making it suitable for applications involving extreme heat or cold.

- Hygienic Properties: In industries like pharmaceuticals and food processing, where cleanliness is paramount, stainless steel's smooth and non-porous surface prevents bacterial growth and facilitates easy sterilization.

Applications Across Industries

The versatility of stainless steel capillary tubes finds expression across a diverse spectrum of industries:- Medical and Healthcare: In medical diagnostics and instrumentation, capillary tubes are indispensable for blood analysis, chromatography, and fluid transfer in intricate surgical procedures.

- Chemical and Petrochemical: Capillary tubes play a vital role in gas chromatography, where precise analysis and separation of chemical compounds are required. They are also used for sample injection in mass spectrometry and as conduits for corrosive fluids in chemical processing plants.

- Aerospace and Automotive: Aerospace and automotive industries rely on capillary tubes for precise fuel and hydraulic fluid delivery, as well as in pneumatic systems and pressure sensors.

- Electronics and Semiconductor: Capillary tubes are integral to semiconductor manufacturing processes, facilitating the deposition of thin films and precise application of chemicals in microfabrication.

- Environmental Monitoring: In environmental monitoring equipment, such as gas analyzers and air quality sensors, capillary tubes enable the accurate measurement and analysis of pollutants and gases.

Manufacturing Excellence

The production of stainless steel capillary tubes involves a series of intricate processes to ensure dimensional accuracy and surface finish:- Material Selection: High-quality stainless steel grades, such as 304 and 316, are chosen for their corrosion resistance and mechanical properties.

- Tube Drawing: The manufacturing process typically begins with tube drawing, where a larger stainless steel tube is pulled through a series of dies to reduce its diameter to the desired dimensions. This process imparts the required smoothness and tolerance to the tube.

- Annealing: To relieve internal stresses and enhance ductility, the drawn tube undergoes annealing, wherein it is heated to a specific temperature and then gradually cooled.

- Surface Treatment: Surface finishing techniques like pickling, passivation, or electro-polishing may be employed to remove surface contaminants and improve corrosion resistance.

- Cutting and Inspection: The finished tubes are cut to the required lengths and subjected to rigorous quality control measures to ensure dimensional accuracy and adherence to specifications.

Advantages of Stainless Steel Capillary Tubes

The unique properties of stainless steel capillary tubes confer several advantages:- Precision: Capillary tubes offer unparalleled precision in fluid handling and analysis, enabling accurate measurement and control of flow rates and volumes.

- Versatility: Their small size and compatibility with a wide range of fluids make capillary tubes suitable for diverse applications across various industries.

- Reliability: Stainless steel's durability and corrosion resistance ensure long-term reliability and minimal maintenance requirements, even in challenging environments.

- Cost-Effectiveness: While stainless steel capillary tubes may have higher initial costs compared to alternatives, their longevity and performance justify the investment over time, resulting in lower overall costs.

- Customization: Manufacturers can tailor stainless steel capillary tubes to meet specific requirements regarding dimensions, surface finish, and material composition, ensuring optimal performance for each application.

Future Trends and Innovations

As industries continue to push the boundaries of precision engineering and miniaturization, stainless steel capillary tubes are poised to play an increasingly vital role. Emerging trends and innovations include:- Nanofluidics: Capillary tubes are at the forefront of nanofluidic research, enabling precise manipulation and analysis of fluids at the nanoscale, with implications for fields such as biotechnology and nanomedicine.

- Additive Manufacturing: Advances in additive manufacturing techniques, such as 3D printing, offer new possibilities for designing and fabricating complex capillary tube geometries with enhanced performance characteristics.

- Smart Materials: Integration of smart materials and sensors within capillary tubes opens up avenues for real-time monitoring and feedback in fluidic systems, enhancing automation and control.

- Miniaturization: The trend towards miniaturization drives demand for even smaller and more precise capillary tubes, enabling the development of compact and portable analytical devices and medical instruments.

- Sustainable Practices: Manufacturers are exploring sustainable alternatives for stainless steel production and processing, minimizing environmental impact while maintaining the integrity and performance of capillary tubes.

Comments

Post a Comment