How Does Capillary Tube Work in Refrigerator?

|

| Capillary Tube Work in Refrigerator |

Introduction:

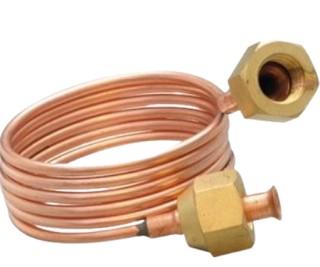

Refrigerators are essential appliances that play a crucial role in preserving food and maintaining freshness. While many components contribute to the efficient operation of a refrigerator, one key element that often goes unnoticed is the capillary tube. Capillary tube are small, narrow tubes that serve as crucial components in the refrigeration cycle, helping regulate the flow of refrigerant and control temperature within the refrigerator. In this comprehensive guide, we'll delve into the functionality of capillary tubes in refrigerators, exploring their design, operation, and significance in maintaining optimal cooling performance.What is a Capillary Tube?

A capillary tube is a thin, narrow tube typically made of copper or aluminum that serves as a metering device in refrigeration systems. Its small diameter and length are carefully designed to regulate the flow of refrigerant from the condenser to the evaporator, controlling the refrigeration cycle's overall efficiency and performance. Capillary tubes are commonly used in refrigerators, air conditioners, and other cooling appliances due to their simplicity, reliability, and cost-effectiveness.How Does a Capillary Tube Work?

The function of a capillary tube in a refrigerator is to create a pressure drop in the refrigerant as it flows from the high-pressure side (condenser) to the low-pressure side (evaporator) of the refrigeration system. This pressure drop causes the refrigerant to undergo a phase change from a high-pressure liquid to a low-pressure vapor, absorbing heat from the refrigerator's interior and cooling the space.The capillary tube's diameter and length are carefully selected to achieve the desired pressure drop and refrigerant flow rate, ensuring optimal cooling performance and energy efficiency. The capillary tube's small size creates resistance to the flow of refrigerant, causing the refrigerant to expand rapidly as it enters the evaporator, resulting in a sudden drop in temperature and the formation of a cold refrigerant vapor.

As the cold refrigerant vapor absorbs heat from the refrigerator's interior, it undergoes a phase change back into a high-pressure liquid, which is then circulated back to the condenser to repeat the refrigeration cycle. The capillary tube acts as a throttling device, regulating the flow of refrigerant and maintaining the desired temperature inside the refrigerator.

Design and Construction of Capillary Tubes:

Capillary tubes are typically made of copper or aluminum due to their excellent thermal conductivity, corrosion resistance, and malleability. The tube's diameter and length are carefully selected based on factors such as the refrigerant type, system pressure, cooling capacity, and temperature requirements of the refrigerator.The inner surface of the capillary tube may be coated with a lubricant or anti-corrosion agent to improve refrigerant flow and protect against oxidation or contamination. Additionally, the capillary tube may be insulated or enclosed within a protective sheath to minimize heat exchange with the surrounding environment and prevent condensation or frost formation.

Capillary tubes come in various sizes and configurations to accommodate different refrigeration systems and applications. The tube's length and diameter play a critical role in determining the pressure drop and refrigerant flow rate, affecting the system's overall efficiency and cooling performance.

Significance of Capillary Tubes in Refrigerators:

Capillary tubes play a crucial role in regulating the flow of refrigerant and controlling temperature within refrigerators. Their compact size, simplicity, and reliability make them ideal metering devices for refrigeration systems, providing precise control over the refrigerant flow and ensuring optimal cooling performance.By creating a pressure drop in the refrigerant as it flows from the condenser to the evaporator, capillary tubes enable the efficient transfer of heat from the refrigerator's interior to the surrounding environment. This process allows refrigerators to maintain the desired temperature range for storing food and beverages while minimizing energy consumption and operating costs.

Capillary tubes also help ensure the proper distribution of refrigerant within the refrigeration system, preventing issues such as uneven cooling, frost formation, and compressor inefficiency. Their straightforward design and operation make them easy to maintain and service, contributing to the longevity and reliability of refrigerators.

Installation and Maintenance Considerations:

Proper installation and maintenance of capillary tubes are essential for ensuring their optimal performance and longevity in refrigerators. When installing a capillary tube, care should be taken to ensure proper sizing, routing, and positioning within the refrigeration system to minimize pressure drop and refrigerant leakage.Regular maintenance tasks such as cleaning, inspection, and lubrication can help prevent issues such as clogging, corrosion, or damage to the capillary tube. Any signs of wear, damage, or deterioration should be promptly addressed to prevent disruptions to the refrigerator's cooling performance.

Conclusion:

In conclusion, capillary tubes play a critical role in regulating the flow of refrigerant and controlling temperature within refrigerators. Their compact size, simplicity, and reliability make them indispensable components of refrigeration systems, enabling efficient cooling performance while minimizing energy consumption and operating costs.By understanding the functionality, design, and significance of capillary tubes in refrigerators, consumers and technicians can make informed decisions when selecting, installing, and maintaining refrigeration systems. With proper sizing, installation, and maintenance, capillary tubes can contribute to the longevity, reliability, and efficiency of refrigerators, ensuring optimal cooling performance and food preservation for years to come.

Comments

Post a Comment